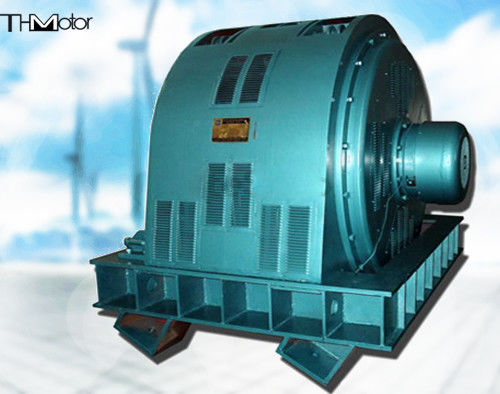

TXZ AC 3-Phase Brushless Synchronous Motor

TXZ large-scale AC 3-phase brushless synchronous motor designed for mining mills, coal mills, cement industry applications, and other heavy-duty operations requiring substantial starting torque.

Product Overview

The TXZ series synchronous motor operates at a main speed of 250r/min and is typically installed at a 30° angle. These motors are primarily used for drainage pumping stations and are available with protection grades IP20, IP21, and IP23.

Structural Configuration

Cooling Method: Motors are cooled using IC81W or IC91W cooling systems.

Protection Class: When the main shell contains exposed live parts, the protection class is IP54. For shells with dustproof measures where all exposed live parts (except windings) are insulated, the protection class can be IP44.

Installation Methods

Available installation configurations include IM7311, IM7315, IM7312, IM7317, and IM7115 to match specific compressor requirements:

- IM7311: Two seat-type bearings, one cylindrical shaft extension, horizontal installation with raised feet and complete base plate

- IM7315: Two seat-type bearings, one flange shaft extension, horizontal installation with raised feet and complete base plate

- IM7312: Two seat-type bearings, two cylindrical shaft extensions, horizontal installation with raised feet and complete base plate

- IM7317: Two seat-type bearings, one flange shaft extension and one cylindrical shaft extension, horizontal installation with raised feet and complete base plate

- IM7115: One seat bearing for non-shaft extension end (sharing bearing with load), one flanged shaft extension, horizontal installation with raised feet and complete base plate

Custom configurations with different cooling methods, protection levels, and installation methods can be manufactured according to specific user requirements.

Motor Construction

The motor features a square box structure with an aesthetically pleasing appearance and compact design. Key components include stator, rotor, AC exciter, rotating commutating disc, static excitation device, junction box, bearings, cooler (with water leakage protector), and base.

The main motor operates as an independent cavity, with the AC exciter and rotating commutating disc positioned outside the non-drive end seat bearing. The main motor utilizes an air duct system that exchanges heat with cooling air through ventilation holes in the motor base. For dual shaft extension drives, the exciter and rotating commutator can be internally integrated. The AC exciter, rotating rectifier disc, and main rotor are coaxially connected, with excitation leads passing through the central lead hole of the shaft.

Motor Series

After-Sales Service

Product Packaging

Certifications

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!