Product Description:

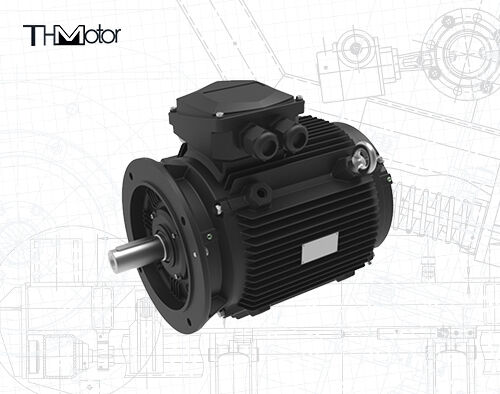

The Permanent Magnet Synchronous Motor is a highly efficient and advanced motor designed to meet the demanding needs of various industrial applications. This motor features a robust Permanent Magnet rotor type, which significantly enhances its performance by providing strong magnetic flux without the need for external excitation. The use of Permanent Magnet technology ensures superior efficiency, reduced energy consumption, and lower operational costs compared to conventional motors. This makes the Permanent Magnet AC Motor an ideal choice for applications requiring precision, reliability, and long-term durability.

One of the standout characteristics of this Permanent Magnet Synchronous Motor is its Work System classified as S9. The S9 duty cycle is indicative of the motor’s capability to handle intermittent periodic duty with starting, acceleration, running at constant load, and braking phases. This allows the motor to perform optimally in applications where variable load and speed conditions are frequent. The ability to operate efficiently under such dynamic conditions highlights the versatility and robustness of the Permanent Magnet AC Motor, making it suitable for a wide range of industrial uses.

The motor is designed to accommodate a broad workpiece range, specifically handling diameters from 1000 mm up to 7000 mm. This wide range makes the motor adaptable for use in heavy-duty machinery and large-scale manufacturing processes. Whether it is employed in metalworking, material handling, or other industrial sectors, the Permanent Magnet AC Motor delivers consistent power output and reliable torque to meet the demands of large workpieces. This adaptability ensures that the motor can be seamlessly integrated into various production lines, enhancing overall operational efficiency.

In terms of product size, the motor comes in a compact 7-inch configuration. This size allows for easier installation and integration within existing machinery setups without compromising on power or performance. The compact design also contributes to space-saving in industrial environments where floor space and equipment footprint are critical considerations. Despite its relatively small size, the motor maintains excellent thermal management and mechanical stability, ensuring sustained performance even under strenuous working conditions.

It is important to note that the current Status Code of this product is 403. This status code indicates specific conditions related to the availability or access to the product which potential users should be aware of. Customers interested in acquiring or learning more about this Permanent Magnet Synchronous Motor are encouraged to contact the supplier or manufacturer directly for detailed information regarding the product’s availability, delivery timelines, and any applicable restrictions. Understanding the Status Code helps in planning procurement and project schedules effectively.

The Permanent Magnet AC Motor technology incorporated in this motor provides several benefits including higher power density, improved efficiency, and reduced maintenance requirements compared to traditional AC motors. The Permanent Magnet rotor eliminates the need for brushes or slip rings, which are common wear components in other motor types. This results in lower downtime and extended service life, contributing to reduced total cost of ownership. Additionally, the motor’s high torque-to-inertia ratio allows for rapid acceleration and precise speed control, which is essential in modern automated systems.

In summary, the Permanent Magnet Synchronous Motor equipped with a Permanent Magnet rotor, operating under the S9 work system, and capable of handling workpieces ranging from 1000 mm to 7000 mm in diameter, represents a sophisticated and reliable solution for industrial motor applications. Its compact 7-inch size, combined with the advanced Permanent Magnet AC Motor technology, ensures superior performance, energy efficiency, and operational flexibility. Despite the current Status Code 403, this motor remains a valuable asset for industries aiming to enhance productivity while minimizing energy consumption and maintenance efforts. The Permanent Magnet AC Motor continues to set the standard for innovation and excellence in the field of electric motor technology.

Features:

- Product Name: Permanent Magnet Synchronous Motor

- Type: Permanent Magnet AC Motor

- Packing: CTN Or Customized

- Work System: S9

- Status Code: 403

- Cabinet Material: 304 Stainless Steel

- Motor Type: Synchronous

- High efficiency Permanent Magnet AC Motor design

- Durable and corrosion-resistant 304 Stainless Steel cabinet

- Reliable performance in various applications with S9 work system

Technical Parameters:

| Inner Package |

Anti-static Bag+foam Fixed |

| Rotor Type |

Permanent Magnet |

| Workpiece Range |

Diameter 1000--7000 Mm |

| Resistance |

50~250Ω |

| Cabinet Material |

304 Stainless Steel |

| Work System |

S9 |

| Product Size |

7inch |

| Motor Type |

Synchronous |

| Packing |

CTN Or Customized |

| Status Code |

403 |

Applications:

The Permanent Magnet Synchronous Motor, featuring a robust cabinet made from 304 stainless steel, is designed to meet the demanding requirements of various industrial and commercial applications. Its durable enclosure ensures excellent resistance to corrosion and environmental factors, making it suitable for use in harsh and challenging conditions. The motor operates on the advanced S9 work system, which guarantees high efficiency, reliability, and consistent performance over extended periods.

This Permanent Magnet AC Motor is particularly well-suited for applications involving large workpieces, with a workpiece range accommodating diameters from 1000 to 7000 mm. This wide range makes it ideal for industries such as manufacturing, automation, and heavy machinery, where large components and assemblies are common. The motor’s high torque capability, despite its classification as a small stepper motor, allows it to deliver powerful and precise motion control, essential for tasks requiring fine positioning and robust mechanical output.

The Permanent Magnet AC Motor’s versatility is further enhanced by the availability of OEM and ODM services, enabling customization to meet specific client requirements. This flexibility ensures that the motor can be tailored to fit unique applications, from specialized machinery to custom-built automation systems. Whether it's integrated into conveyor systems, robotics, or precision manufacturing equipment, this motor provides reliable and efficient operation.

In terms of application scenarios, this Permanent Magnet AC Motor excels in environments where high torque and precision are critical. It is frequently utilized in CNC machinery, robotic arms, packaging equipment, and automated assembly lines, where consistent and accurate motor control directly impacts productivity and product quality. Additionally, its stainless steel cabinet makes it suitable for food processing, pharmaceutical, and other hygienic applications where cleanliness and durability are paramount.

Overall, the Permanent Magnet Synchronous Motor is a versatile and powerful solution that combines advanced technology, durable construction, and customizable options. Its ability to handle large workpiece diameters, deliver high torque, and operate efficiently in diverse environments makes it an indispensable component across a wide spectrum of industries and application occasions.

Customization:

Our Permanent Magnet AC Motor customization services cater to a wide range of requirements to ensure optimal performance and reliability. We offer workpiece diameters ranging from 1000 to 7000 mm, allowing flexibility for various industrial applications. The motor power options include 30HP and 22kW, providing efficient and powerful operation tailored to your needs.

The shaft diameter can be customized between 25 and 100 mm to fit specific mechanical configurations. As a synchronous motor, our Permanent Magnet AC Motor delivers precise speed control and high efficiency. Additionally, we specialize in small stepper motors with high torque, ensuring your application benefits from enhanced performance and durability.

By choosing our Permanent Magnet AC Motor customization services, you receive a motor designed to meet your exact specifications, combining advanced technology with reliable craftsmanship to support your operational goals.

Support and Services:

Our Permanent Magnet Synchronous Motors (PMSMs) are designed to deliver high efficiency, reliability, and performance across a wide range of industrial applications. To ensure optimal operation and longevity of your motor, we provide comprehensive technical support and services.

Our technical support team is available to assist with installation guidance, troubleshooting, and maintenance procedures. We offer detailed product documentation, including user manuals, wiring diagrams, and performance data sheets to help you understand and utilize your motor effectively.

For maintenance, we recommend regular inspection of motor bearings, cooling systems, and electrical connections to prevent unexpected downtime. Our experts can provide tailored maintenance schedules based on your specific application and operating conditions.

In case of any operational issues or technical inquiries, our support engineers are equipped to provide remote diagnostics and on-site assistance to quickly resolve any problems.

We also offer training programs and workshops to help your team gain in-depth knowledge of PMSM technology, installation best practices, and troubleshooting techniques.

Replacement parts and upgrade services are available to enhance the performance and extend the service life of your motor. Please ensure that any replacements or repairs are conducted using genuine parts to maintain product integrity.

By choosing our Permanent Magnet Synchronous Motor, you benefit from not only a high-quality product but also a dedicated support network committed to your success.

Packing and Shipping:

The Permanent Magnet Synchronous Motor (PMSM) is carefully packaged to ensure safe delivery and optimal protection during transportation. Each motor is first wrapped in anti-static and moisture-resistant materials to prevent damage from environmental factors. The wrapped motor is then placed in a custom-fitted foam insert inside a sturdy, double-walled corrugated cardboard box to minimize movement and absorb shocks.

For larger or heavier models, the motor is secured on a wooden pallet with additional padding and protective corner guards to enhance stability and prevent impact damage. All packaging materials comply with international shipping standards to guarantee safe handling throughout the shipping process.

Shipping is conducted through reliable logistics partners with options for express or standard delivery, depending on customer requirements. Each shipment is accompanied by detailed documentation, including a packing list, user manual, and warranty information, ensuring a smooth and transparent delivery experience.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!